Optical Sapphire with Highest Transparancey in the Near Infrared

A Doctoral Student requested we quote the following sapphire substrate:

I would like to request 3 quotes for optical sapphire. Quote 1: DSP, 100um thickness, 2mm diameter, pricing for 5, 10 pc Quote 2: DSP, 300um thickness, 2mm diameter, pricing for 5, 10 pc Quote 3: DSP, 500um thickness, 2mm diameter, pricing for 5, 10 pc Regarding the crystal orientation, I am interested in whichever has the highest transparency in the near IR (I believe this would be A-plane based on the info on your website). Also, can you provide example spectral properties for this material? I'm specifically interested in near and mid IR absorptance.

Also, do you happen to have spectral transmission data available?

Reference #264269 for specs and pricing.

Where to Buy A-Plane Sapphire?

A-plane sapphire can be hard to find. UniversityWafer, Inc. has a large selection of a-plane sapphire in stock.

Please email us the specs that you need.

What Is A-Plane Sapphire?

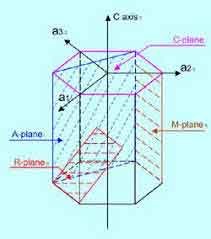

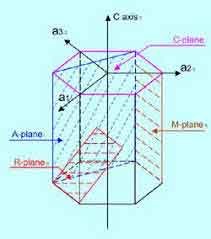

A-plane sapphire is the most popular type of sapphire. It is used for optical devices and is resistant to high-temperature. Its low resistance and high thermal conductivity make it the preferred material for semiconductors. A-plane sapphire is also a more suitable material for electronics. The c-plane sapphire is more conductive than a-plane sapphire, and is a perfect choice for many different applications. The plane that is perpendicular to the A-axis, containing the C-axis Sapphire. A-plane Sapphire orientations are widely used in optoelectronic applications.

Our A-plane sapphire wafers are perfect for optoelectronic applications. They have low resistance and high thermal conductivity, making them the ideal choice for semiconductors.

We have a large selection of A-plane wafers in stock.

A-Plane Sapphire Substrate and Wafers For LED Applications

A plane sapphire is the most widely used type of sapphire in the world, and is a perfect choice for a variety of industrial applications. Because of its high optical clarity and durability, it is a desirable material for these purposes. Its advantages include the ease of processing and cost. These properties make it an excellent choice for many different industries. However, one downside is the brittleness of c-plane sapphire, which can result in a broken product.

The primary requirement for sapphire wafers is that they must be oriented in a plane. This is done by using a special tool for slicing and polishing the crystal. This process involves trimming and polishing the edge into a circular arc and improving the flatness of the substrate. Once the sapphire wafers have been cut, cleaning is required. This is to remove any contamination and make the surface smooth.

A-plane sapphire is available in thick and thin wafers. The substrates are available in single or double side polished versions. Both types of sapphire are highly scratch resistant, so they are excellent for a wide range of applications. A-plane sapphire is a popular choice for applications requiring high thermal conductivity and resistance. The substrates are also more scratch resistant than c-plane sapphire, and are suitable for laser cutting.

Sapphire is the best material for a variety of crystalline structures. The a-plane sapphire is very hard and durable. It has a high electrical insulation and has low dielectric loss. It is also a highly conductive material, and can be used for hybrid microelectronics. And the c-plane sapphire is the most expensive of the three types.

The a-plane sapphire is the hardest type of sapphire. Its abrasiveness makes it a poor material for many applications. A-plane sapphire has been found to be more durable and optically superior than c-plane sapphire. This material can be a good choice for various LED applications. So, if you are looking for a material with high optical qualities, you should consider a C-plane sapphire.

It is also used in a variety of applications. It is an excellent material for window panes, and a plane sapphire window is an excellent replacement for quartz and glass. It is also a strong material for a plane's windshield. Aside from the optical qualities, a sapphire waveplate is a great choice for high-precision windows. Its high temperature and high pressure resistance make it an excellent choice for a number of different purposes.

Sapphire is available in various colors. A deep blue sapphire is composed of titanium and iron. The physical properties of a sapphire determine its orientation. It is possible to find a plane sapphire in a wide variety of colors. Generally, the color of a plane sapphire is called a "zero degree" grade. In a supercritical environment, a high-grade sapphire is transparent and does not exhibit a high level of lattice distortion.

A plane sapphire has many applications and benefits. It is highly transparent and has a high resistance, which makes it an excellent choice for optical devices. It is a very versatile material for a variety of applications. There are no limits to what it can do! In fact, a sapphire can be used to make anything from sunglasses to car parts. But it is also a good material for solar panels.

Sapphires can also be used to create microelectronics. Whether you're looking for a crystal for a watch or a ring, you'll find an excellent source of a plane sapphire. Despite its low price, a plane sapphire is a good choice for microelectromechanical devices. These crystalline materials are ideal for high-precision optical components, including lasers.

There are many benefits of a plane sapphire. It has a uniform dielectric constant, which is a good quality for semiconductor devices. Furthermore, it is resistant to high temperatures, which makes it a good choice for laser-cutting. The A-plane sapphire is also the least expensive of the three sapphires. The aplane variety is the most common type for optical applications, and is the most commonly used.

What is the Difference Between C-Plane and A-Plane Sapphire?

There are two types of sapphire: c-plane and a-plane sapphire. While c-plane sapphire is the most expensive of the three types, it is also the most durable. The difference lies in the micro-roughness of 0.35 nm. However, a-plane sapphire is less expensive than the a-plane variety, and this is because it is more brittle.

The first sapphire type is the C-plane, which is the most common. While the two types of sapphire have similar properties, they are characterized by different crystalline structures. The crystalline form is more resistant to heat and pressure than the a-plane form. This makes c-plane sapphire a superior choice for microelectronic applications. And while C-plane sapphire is the most common type, a-plane sapphire is the best choice for hybrid microelectronics. A-plane sapphires have a high thermal conductivity, which makes them an excellent choice for solar cells and other high-tech applications.

The C-plane sapphire has a uniform distribution of bandgaps. This type is the least expensive of the three types and is widely used for high-precision optical components. This sapphire is highly scratch-resistant and resists thermal shock. Its properties make it an excellent choice for high-precision optical components. Its low resistance also makes it ideal for laser cutting.

A-plane sapphire is a type of crystal with hexagonal and rhombohedral structures. The orientation of the crystal determines the sapphire's properties. Because sapphire offers a wide range of lattice constants, it is an excellent substrate for many types of semiconductor devices. A-plane sapphire has uniform dielectric constant and high insulation, making it the best choice for semiconductor manufacturing. In addition, high-Tc superconductors can be grown on a-plane sapphire.

Unlike c-plane sapphire, a-plane sapphire is more transparent. This sapphire is used for high-end electronics, such as in semiconductor chips. In addition to these advantages, c-plane sapphire is also more durable. In addition, it has lower thermal conductivity, which makes it a preferred choice in many applications. Its low thermal conductivity also makes it ideal for some applications.

A-plane sapphire is the least expensive sapphire type. Its high MRR and low Sa make it the most popular material for laser-cutting and other high-precision optical components. In addition to its high resistance, it is also highly transparent. This property makes it ideal for a wide range of applications. If you're looking for a sapphire that is transparent, choose a C-plane sapphire.

A-plane sapphire is the most commonly used sapphire variety. Its structure makes it an ideal material for a variety of applications. Its facets are highly polished, making it useful for a variety of applications. A-plane sapphire is the easiest to polish, and it can be used in a range of applications. But it is not recommended for high-temperature laser-cutting.

Another type of sapphire is c-plane. It has an a-plane crystal. This type of sapphire is the least expensive of the three types. It is also the least expensive of the three. It is widely used in high-precision optical applications, as it has the highest MRR of all sapphires. It is also the most affordable of the three.

A-plane sapphire is the most common of the three types. Its hardness is Mohs 9. It is also extremely hard, so it is very useful for microelectronics. Its a-plane sapphire is the most commonly used variety, and it is often fabricated in 0.4 mm thickness. It is a very durable material, and is often used in laser cutting processes.

C-plane sapphire is the most common type of sapphire. It is the least expensive type and is used in a wide variety of applications, including IR applications. Its asymmetrical sapphire has a pronounced crystalline structure and is best for IR applications. For these reasons, it is more expensive to produce than asymmetrical sapphire.

How do Researchers Use A-Plane Sapphire Substrates?

Chemical Vapor Deposition (CVD) has been used by researchers to grow AlGaN epi-layers on a-plane sapphire. And to grow MoS2 to make more efficient electronic devices.

Reseachers have used a-plane sapphire to grow Polycrystalline Diamond Thin Film using the CVD process.

Ion Beam Milling of Single-Crystal Sapphire on A-Plane Sapphire

The removal rate of material (MRR) is the speed at which material is removed from the surface. The surface roughness (Sa) is how rough the surface is after the material is removed. The MRR of A-plane sapphire is slightly higher than that of C-plane and M-plane sapphire. The Sa of A-plane sapphire after FIB treatment is the smallest among the three different crystal orientations. These results imply that A-plane sapphire allows easier material removal during FIB milling compared with C-plane and M-plane sapphires. Moreover, the surface quality of A-plane sapphire after FIB milling is better than that of C-plane and M-plane sapphires. The theoretical calculation results show that the removal energy of aluminum ions and oxygen ions per square nanometer on the outermost surface of A-plane sapphire is the smallest. This also implies that material is more easily removed from the surface of A-plane sapphire than the surface of C-plane and M-plane sapphires by FIB milling.