What is Extreme Ultraviolet Lithography (EUV)?

What is EUV Lithography?

Among the challenges of EUV lithography are the difficulties in creating the EUV light. Despite this, the technology is close to commercialization and is at the brink of volume chip manufacturing. This makes it crucial to continue working on the technology in order to realize this goal. Even though it is so hard to manufacture an ultraviolet-emitting device, the process is crucial for obtaining high-quality results.

We have the substrates you need!

Get Your Quote FAST!

Does Intel Use Extreme Ultraviolet Lithography?

The answer to the question: "Does Intel use extreme ultraviolet lithography?" is a resounding yes. It's an advanced fabrication technique that is used in the creation of next-generation chips. EUV uses light with a very small wavelength to make micro-features in semiconductors. The process is also capable of creating very large features, and Intel is planning to use it to make its own processors in the future.

The process is not without its drawbacks, and one of them is that it's a difficult light to control. For many companies, the main issue with using EUV is the downtime of the machines, which has been a stumbling block to the adoption of this process. However, the technology is now being used by Intel and will soon be used in high-volume manufacturing. While EUV isn't perfect, it is promising and will help chip makers move toward producing a more reliable and advanced chip.

While EUV technology isn't perfect, it is already widely used in the semiconductor industry, and Intel is expected to be a leading customer of this technology for chipsets. Besides being highly accurate, EUV also has a low cost of production. The process can be used for a wide variety of parts and has a very low yield. The next phase of the process involves a conversion from deep UV plants to EUV ones.

The EUV process has numerous advantages. It makes it possible to produce processors that are quick and efficient. This process uses a laser that is 13.5 nanometers in wavelength. This is smaller than deep UV and is therefore ideal for putting tiny transistors on complex chips. This technique also has higher resolution and is capable of a single exposure. It can also be used to make larger chips, which is essential in the manufacture of smartphones.

The technology uses high-NA EUV lasers, which have an ultraviolet light wavelength of 13.5 nanometers, to print lines on semiconductors. The increased intensity of the EUV beams will allow them to accurately print lines and reduce their yield. Ultimately, this will increase the quality of the chipsets and make them more competitive in the market. Further, the EUV process will help Intel achieve this goal.

The EUV process is used to create more efficient and quick processors. The process uses a laser with a 13.5 nanometer wavelength. It is a much smaller wavelength than deep UV. This laser is useful for manufacturing chip-scale transistors. It allows for better resolution and a more precise process. It's the future of computing and is the best way to compete with Qualcomm and MediaTek.

Developed by Philips and Intel, this technology is capable of producing processors with faster response time. Its small wavelength allows for higher accuracy, and it's cheaper to produce than other semiconductor technologies. Moreover, it's faster and more efficient than deep UV. A major benefit of this method is its high-resolution. In addition to this, EUV has lower yield than deep UV and can improve the accuracy of printed lines.

The EUV tool, which is used for the fabrication of microchips, has been produced by ASML exclusively for Intel. It's made up of a high-precision laser with a 13.5 nanometer wavelength. It can print very thin and small features in semiconductors. It's also fast and efficient. A typical chip takes five minutes for a 10-nanometer chip to be created.

While EUV is easier to control, the high-NA laser will increase the yield. Due to its high-NA laser wavelength, EUV has less downtime than deep UV. This means that it will be cheaper to produce the same number of chips. Then, the manufacturer will need to convert existing deep UV plants to use the EUV process. When it is ready to scale up production, the company will be able to reduce its costs further.

The EUV technology isn't used in every chip, but it has helped the company to improve the production of chips by reducing the size of chips. The shorter the wavelength, the smaller the chip's size, and its overall performance. Aside from this, EUV technology is cheaper than DUV, so it will not impact chip prices. It will not require a license to be used. And it will be able to make chips in any size.

What is Extreme Ultraviolet Lithography (EUV) Technology?

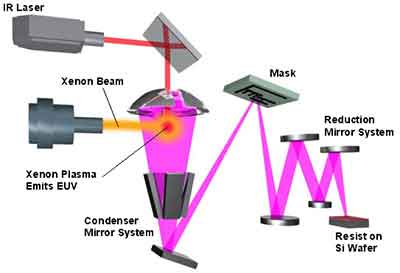

The term "extreme ultraviolet" (EUV) lithography refers to the exposure of circuit patterns with a wavelength of 13.5 nanometers. This process is not possible with conventional optical lithography, and requires various element technologies. The technology uses a laser to heat xenon gas to form plasma, which emits light at 13 nanometers. This material is then etched onto a silicon wafer.

The research report on the Extreme Ultraviolet Lithography Market includes different segments based on product type, application, and region. It also analyzes different factors that will help the market grow. As a result, you can have a thorough understanding of the industry and make the right investment decision. Here are some of the major factors to consider for analyzing the EUV lithography market.

What is The Market Trends for Extreme Ultraviolet Lithography (EUV)?

First, it's important to understand what EUV lithography is. This new technology uses extremely powerful light with a wavelength of 13.5 nanometers. The technology allows for the creation of complex patterns, including intricate patterns. It also makes it easier to highlight integrated circuits on semiconductor wafers. A recent report estimates the global EUV lithography market to reach $29.4 Mn by 2028. The market for extreme ultraviolet lithography is anticipated to reach nearly $29 billion by 2028, according to a report from the Australian Communications and Media Authority.

The process is used in manufacturing semiconductors. The extreme ultraviolet lithography market will grow at a 15% CAGR over the next five years. This technology uses a wide range of UV wavelengths to produce circuit patterns. This technology is widely used for memory chips and storage capacity in semiconductors. However, the future of EUV lithography is uncertain. There are some concerns associated with this new technique, but the overall growth of the industry is expected to be at a rapid pace.

How Long Has Extreme Ultraviolet Lithography (EUV) Been Around?

The technology behind this technology has been around for years, and the emergence of high-end microprocessors has almost squeezed silicon's life. The current technology used to produce microprocessors will reach its limit by 2005, so chipmakers will have to find other technologies to pack more transistors onto silicon. One of these new technologies is extreme ultraviolet lithography. In the meantime, we have a new device on the horizon.

What Is Extreme Ultraviolet Lithography (EUV) Used For?

The technology uses extremely high-powered light to create high-quality semiconductors. Its main applications include microprocessors and semiconductors. The technology is also used to make LEDs, photonic devices, and other electronics products. Its benefits also include improved performance and lower cost. The process also allows for the development of new designs that are able to withstand higher heat. If you're wondering what this technology is, this report will provide you with all the information you need to succeed in this new field.

The technology used to manufacture the microprocessors used in smartphones. The technology is also used to make memory chips for compact electronic devices. In addition to the use of extreme ultraviolet lithography in smartphones, the technology is also used in the manufacturing of compact electronics. Furthermore, the increasing number of smartphone users globally and in developing countries is expected to fuel the growth of the market. Further, growing research & development activities will further boost the market.

The technology is widely used for microprocessors. The process is an important part of semiconductor production. The EUV process can produce nanometer-scale chips. It is also used to print complex patterns and highlight integrated circuits on semiconductor wafers.

The technology is used for printing complex patterns and highlighting integrated circuits in semiconductors. The global extreme ultraviolet lithography market is expected to grow at a CAGR of 5.8 percent over the next five years. In addition, the increasing number of smartphone users is expected to drive the market growth in the next few years. The research & development activities will also increase the level of sophistication of EUV lithography systems.

The technology uses high-frequency ultraviolet light, a wavelength of 13.5 nanometers. It has a broader range of applications, including the manufacture of semiconductors. The technology has the potential to revolutionize manufacturing. A high-quality semiconductor will have a high-quality surface, and the ability to print complex patterns on a small area. The resulting semiconductor will be more efficient. It will increase energy efficiency.

Why Extreme Ultraviolet Lithography is So Difficult

EUV lithography is a complex technology that can have some serious problems. Using these wavelengths in a semiconductor process is problematic because glass absorbs them. Mirrors also cannot be used because the light is so small that they can't be properly focused. To make this process more practical, it is necessary to apply complicated coatings that will better reflect the light. This is one of the reasons why the European Union has been a major force in EUV research.

EUV lithography is a complex technology that can have some serious problems. Using these wavelengths in a semiconductor process is problematic because glass absorbs them. Mirrors also cannot be used because the light is so small that they can't be properly focused. To make this process more practical, it is necessary to apply complicated coatings that will better reflect the light. This is one of the reasons why the European Union has been a major force in EUV research.

To perform EUV lithography, a laser with a wavelength of 13.5 nm is used. This allows very fine circuit patterns to be exposed. This is not possible using conventional optical lithography. It requires a number of element technologies, which can be extremely costly. In the meantime, it is worth investing in this technology because it is a step toward advancing electronics and the world's technology.

The technology for EUV lithography is truly amazing. It involves a generator that emits 50,000 tiny droplets of molten tin every second. Each droplet is blasted twice by a high-powered laser, which vaporizes it and turns it into a plasma. Each particle of tin creates a thin layer of light that bounces through a series of mirrors. The rays hit the silicon wafer with an accuracy of 1 mm or better.

A number of research groups are preparing to use shorter wavelengths. Fraunhofer institutions in Switzerland completed a project titled "Beyond EUV" in 2016, where they worked on new materials and plasma sources. The group aims to develop a 6.7 nm photoresist. The Swiss group presented their research in 2015, and has released a roadmap for further development.

The wavelength is the most important parameter in EUV lithography. Its short wavelength is the key to a successful process. The short-wavelength UV lamps, for example, can only be used for a few minutes at a time. Compared to the long-wavelength lasers used for electron beam lithography, the former is much more powerful. Achieving this feat requires a laser with an average power of 13 nm.

The technology requires major investment. In order to be successful, the process must be able to produce defect-free photoresists. As the result, EUV is difficult to develop and requires large amounts of research and development. In order to succeed, it must be cost-effective. However, this technology has the potential to revolutionize the semiconductor industry. There are many challenges in this new process.

For decades, chemically amplified resists have been the workhorses of advanced semiconductor lithography. To overcome this issue, a new platform was developed in 2016. A new resist was developed to avoid excessive photon shot noise. Both of these challenges made it difficult for the technology to become cost-effective. But the technology is still a step in the right direction. It has the potential to revolutionize the electronics manufacturing industry.

The most important challenge in EUV lithography is the lack of sensitivity of the EUV laser. Due to this, a high-sensitivity resist will require moderate doses, which may be expensive for certain types of electronics. It is also possible to use multiple layers of EUV resist. Therefore, the new technology is a viable option for many companies. But the question is why it is so difficult?

Another major hurdle for EUV lithography is the need for a high-power light source. Initially, discharge-plasma sources were touted as a viable option, but later found that they were not efficient for upscaling. In fact, the biggest obstacle to EUV lithography is the wavelength itself. Until the target half-pitch value is 22 nm, there are only a few examples of such devices.

Extreme Ultraviolet Lithography Machines

The development of EUV lithography machines is a hot topic in the semiconductor industry. The semiconductor industry has vacillated between hoping EUV will save Moore's Law and despairing that it will never be ready. Companies such as Samsung, GlobalFoundries, and Taiwan Semiconductor Manufacturing Co. are claiming they will have EUV tools ready to use in 2018. But what is the status of the technology?

The development of EUV lithography machines started in the early 1980s, when researchers began to experiment with the technology. In 1994, a group of semiconductor companies delivered a prototype, which proved that EUV lithography was viable. From there, industry pushed ahead with the development of the technology. Today, these machines are used in chip manufacturing. But despite the technical difficulties, they are becoming increasingly popular. And there are a host of benefits.

One of the biggest advantages of EUV is the ability to print very fine features on a wafer. The EUV light, which is at 13.5 nanometers in wavelength, enables the exposure of tiny circuit patterns that can't be seen in conventional optical lithography. In other words, EUV is a very efficient process. Aside from cutting down the production cost, it allows companies to make more advanced products.

Another major advantage of EUV lithography is its high-resolution. Its improved line geometry can reduce the chip size by five to ten times. This helps the chip's processing speed, component density, and energy usage. ASML, for example, is a world leader in lithography equipment with net sales of $3.2 billion in the third quarter of 2019. The company plans to use its new machine to make the first batch of chips by 2023. As long as the machine has enough resolution to produce millions of tiny components, it should be able to produce chips more efficiently than ever.

In addition to forming computer chips, EUV lithography machines also write patterns on photomasks. Since transistors are five nanometers in length, EUV machines can create a large number of components per wafer. As a result, this technology is highly efficient and can produce countless microchips in less time. The process is cost-effective and is widely used in the semiconductor industry. The current cost of the machine is around $3.5 million.

However, the technology is not yet mature. Its development is still in its infancy. There are still a few major limitations, but it is close to commercialization. The technology will only become more affordable as it improves cooling and laser power efficiency. Its success is dependent on the level of improvement of EUV lithography. It will also be more efficient when it comes to creating high-resolution images.

Currently, the technology requires a very powerful light source. In the early 2000s, discharge-plasma-based sources were touted as the most efficient way to achieve high-quality EUV lithography. But since EUV technology requires many element technologies, they are expensive. While these machines are very advanced, they are not yet ready to make chips. It is still early days to tell how they will benefit from this new technique, but there are many potential benefits.

The new machine from ASML is introducing a new process that uses more energy and lowers energy. The process requires a lot of power and a high dose, but the higher dose means lower throughput. The difference in the resolution is due to the difference in the light intensity between the two lines. The NXE3400 system is a high-resolution device, but the NXE3400 is a lower-resolution system.

The technology's resolution and throughput are the major issues that plague EUV lithography. There are numerous challenges to EUV lithography's throughput. It requires a high-power light source. In addition to this, the wavelength of the EUV light must be high to achieve quality imaging. A machine with this wavelength can produce features as small as one micron. Therefore, the machine must be able to reach a very high throughput rate.

China plans to purchase an extreme ultraviolet lithography machine from the Netherlands, but it was unable to do so due to US restrictions. Its share price has continued to rise and it is expected to sell these machines to other manufacturers in 2030. And China is also working on the development of the technology itself. TSMC's recent investments have made it one of the leading semiconductor companies in the world. In fact, the company's EUV lithography equipment costing just a fraction of that in South Korea.