4H Silicon Carbide (SiC) Substrates to Fabricate Integrated Photonic Components and Devices

A Electrical and Computer Engineering Ph.D candidate requested the following quote:

I want to use the silicon carbide for integrated photonic components and devices such as waveguides and ring resonators. Therefore, I am quite interested in the 4H silicon carbide on insulator (4H-SiCOI) wafers, which has 4H-SiC thin films on top of the SiO2 on Si carrier wafers. I have read that one approach to get this kind of wafers is to bond the 4H-SiC wafers with the SiO2 on Si carrier wafers and then to grind the 4H-SiC wafers down to the thickness of several microns. I wonder whether you can provide such a kind of wafers.

The diameter can either be 4-inch or 2-inch based on your inventory. The type of 4H-SiC wafer should be insulating with 0-deg off axis. The thermally grown SiO2 should at least be 1um thick with good surface conditions. And if possible, please quote for only 1 wafer.

Reference #268777 for specs and pricing.

Silicon Carbide Wafers Applications

SiC wafers are used in power applications including:

UniversityWafer, Inc. dummy and research grade silicon carbide wafers and ingots are of the highest quality guaranteed!

Why buy your SiC substrates in volume if you don't have to? Buy now and save!

Some of SiC Wafers Current and Future Uses

Unmanned Aerial Vehicles (UAV)

Future SiC applications include smaller speed controllers for the  remote-control aircraft and UAV hobbyists. These stronger, smaller speed controllers can work with at higher voltage and currents in compact spaces. For UAV drone racing SiC power devices hold great promise for their increased performance, maximized speed and increased endurance.

remote-control aircraft and UAV hobbyists. These stronger, smaller speed controllers can work with at higher voltage and currents in compact spaces. For UAV drone racing SiC power devices hold great promise for their increased performance, maximized speed and increased endurance.

Formula E Racing Implementing Silicon Carbide Based Power Devices

For battery operated UAVs and electric vehicles SiC’s low power loss, and reduced weight equates to longer battery life and more efficient operations. Estimates from electric formula-one racing see a 30% increase in power inverters electric performanc

Increased Efficiency in Smaller Package Using Silicon Carbide Schottky Diodes

Unliked Silicon-based diodes, Silicon Carbide Schottky Diodes have a smaller capacitive charge (Qc). This reduces switching loss, thus enabling high-speed switching operation. SiC devices are aslo more stable at all temperatures resulting in contstant perfomance that is much better than their Silicon-based equivalent.

Helping Scientist Source the Correct SiC Wafers

Researcher Question: Can your SiC wafers can be used for pitaxial growth of GaN and InN with molecular beam epitaxy techneque (MBE). Answer YES!

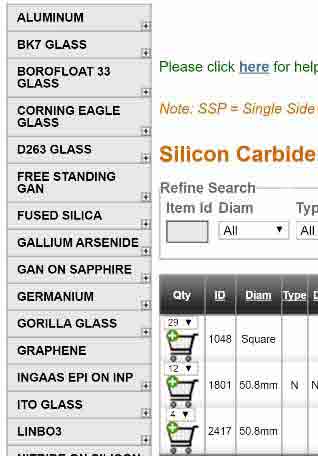

- 6" SiC, 4H-N, Dummy grade

- 6" SiC, 4H-N, Research grade

- 4" SiC, 4H-N Dummy grade

- 4" SiC, 4H-N, Research grade

- 3" SiC, 4H-N, Dummy grade

- 3" SiC, 4H-N, Research grade

- 2" SiC, 4H-N, Dummy grade

- 2" SiC, 4H-N, Research grade

- 5mm Sq. All Grades

- Dicing services available

Recent Press Release - Silicon Carbide Substrate Applications for Today and Tomorrow

UniversityWafer, Inc. distributes affordable single crystal silicon carbide wafers.

Researchers of Unmanned aerial vehicles, electric vehicles and other e-mobility applications will all find benefit in inexpensive silicon carbide wafers.

UniversityWafer, Inc. along with its partners is now distributing silicon carbide substrates up to 150mm in diameter of all grades for all applications. Silicon carbide (SiC) wafers work great in power devices that have to be engineered into tight spaces.

Researchers now have the flexibility to design much smaller Power devices used in aerospace including Unmanned Aerial Vehicles and automotive. Unlike conventional silicon based power devices, SiC allows for miniaturization of current Silicon devices.

SiC devices can withstand higher electric fields resulting in extremely low power loss at higher temperatures. For battery operated UAVs and electric vehicles SiC’s low power loss, and reduced weight equates to longer battery life and more efficient operations. Estimates from electric formula-one racing see a 30% increase in power inverters electric performance.

Future SiC applications include smaller speed controllers for the remote-control aircraft and UAV hobbyists. These stronger, smaller speed controllers can work with at higher voltage and currents in compact spaces. For UAV drone racing SiC power devices hold great promise for their increased performance, maximized speed and increased endurance.

The heat properties of SiC improve overall electronics so you can reach higher performance with your electric motors.

MIT has conducted research in micro-turbine, engine-on-chip technology using silicon. Studies have proven that Silicon Carbide substrates handles the heat produced by this miniature turbine more efficiently.

Silicon Carbide wafers an help researchers develop much simpler and more efficient power devices that could provide rapid charging of batteries for toys, consumer, industrial and military applications.

By distributing inexpensive Silicon Carbide wafers UniversityWafer, Inc. believes it can help speed along research and development.