VGF (Vertical Gradient Freeze) Grown Gallium Arsenide (GaAs)

VGF Grown Gallium Arsenide (GaAs)

UniversityWafer, Inc. and are partners manufacture semi-insulating and Semiconducting Gallium Arsenide wafers and ingots by LEC (Liquid Encapsulated Czochralsky) or VGF (Vertical Gradient Freeze) growth method.

Required electrical parameters are achieved through high purity 6N input material (Gallium and Arsenic). In order to attain the chosen level of concentration, the dopants like Zinc, Silicon and Tellurium are used.

Get Your Quote FAST!

What is Vertical Gradient Freeze?

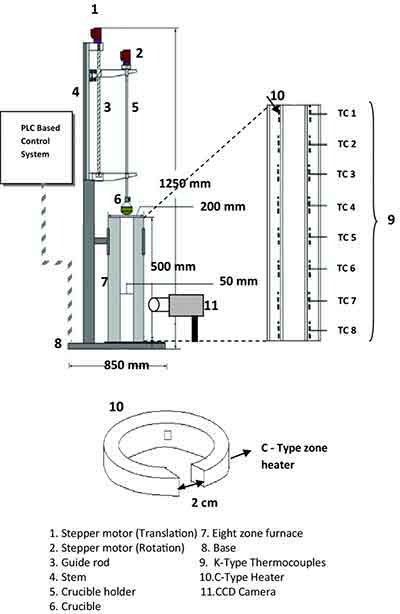

The apparatus used in a vertical gradient freeze experiment comprises a frame 10, a base plate 11, and a pair of guide rails. On the upper portion of the guide rails are two supports - upper and lower. An electric furnace is mounted on the upper support of the apparatus. Guide rails guide the upper and lower sliders. The lower slider is connected to the upper support by a driving screw 14.

Objectives

VGF, or Vertical Gradient Freeze, is a type of crystal growth process that involves the simultaneous formation of a crystal and a melt. This process is characterized by time-varying spatial extents of the crystal and melt, and involves the solution of two coupled free boundary problems. During this process, the solution is typically obtained by a finite element method that transforms a simplified spatially distributed representation of the system into a spatially lumped representation. To optimize the growth process, a nonlinear control problem is formulated, taking into account the limitations of the process and attempting to achieve a balance between different quality objectives.

Modification of Bridgman Method

A more comprehensive study of Bridgman's method has been performed with the use of a modified method by Miss Elam. She has successfully grown single crystals in copper, silver and gold. This new method eliminates strain and produces a crystal without twins. The findings support the theory behind Bridgman's method. Here are the key parameters involved. You can find these values in Table 1.

The modified Bridgman method starts with solidifying polycrystalline material in a crucible, which is heated to a temperature above the melting point and then cooled from a seed crystal. This method allows for greater control of the temperature gradient at the melt/crystal interface. Once crystals are formed, they undergo a growth phase that involves the addition of new atoms, ions and polymer strings.

The modified Bridgman process can be used to grow large PMO single crystals. The feed material for this process has a strict stoichiometric composition, which limits the volatilization of melts. The temperature gradient is 20 40degC/cm across the solid-liquid interface, and optical uniformity is high. This modification of Bridgman method is promising for mass production of PMO crystals.

A polycrystalline specimen of solid argon has been grown using Bridgman's method. The result is a polycrystalline specimen with grains up to 4 mm in diameter. The experimental data obtained in this process are presented in this paper. The results demonstrate the effectiveness of the method for achieving high-quality single crystals. This new method also improves crystal homogeneity. Using a 30x30x1 mm plate, we have successfully grown PMNT 67/33 with good-quality single crystals and have measured coupling factors of k3394% in the longitudinal mode and k33'86% in the beam mode.

A new furnace is essential for this method. Using a high-pressure Bridgman crystal growth furnace allows us to obtain more pressure without sacrificing accuracy. The furnace is typically equipped with two motors with varying transmission ratios. The furnaces in BV-HTRV are mounted on a pulling device. They are able to move samples quickly with a speed of 10 mm/s.

A modified horizontal Bridgman method is another common technique. In this method, the crystals are grown at high temperatures without obtaining a low-temperature arsenic zone. Moreover, this modified method does not produce a low-temperature arsenic zone, and thus does not provide the desired quality single crystal. This technique does not provide low-temperature arsenic zone, which is necessary for semiconductor devices. However, the high temperature requires a very high doping concentration and low etch pit density. It is difficult to produce high-purity GaAs crystals.

This modification of the Bridgman method was applied to CdTe2O5 single crystal growth. This technique involved melting the powder mixture in a platinum/gold crucible with a customized insulated chamber. The resulting mica-shaped single crystals were then extracted and studied. One problem with this technique was the evaporation of TeO2 and CdO. These two compounds were compared to the VB method, and the as-grown crystals have very good structural properties.

Process for Growing GaAs Single Crystal

A numerical model is developed to predict the dislocation density in a single crystal grown using the vertical gradient freeze method. The dislocation is a common semiconductor defect and the perfect adjustment of crystal growth parameters is crucial to the production of near-dislocation-free crystals. The dislocation densities in various crystals grown by different parameters can be compared to the experimental results to gain insight into the growth process.

The vertical gradient freeze process is one of the most effective methods of growing single crystals in bulk quantities. The process yields large, seeded 50-mm-diameter crystals with low dislocation density and good radial uniformity. The undoped semi-insulating GaAs produced from this process resists type conversion and has high thermal stability, which is vital for semiconductor devices. Another benefit of this process is its ability to generate large amounts of semi-insulating GaAs, which can be used in medical equipment and solar cells.

What are Vertical Gradient Freeze (VGF) Advantages?

Another advantage of the VGF process is its linear electro-optic effect. A linear electro-optic tensor represents the change in refractive index under an electric field. This effect is observed for both parallel and slanted light. Without an electric field, the refractive index is n0. This feature allows better control over crystal properties and is a great tool for a variety of applications.

A vertical gradient freeze method for growing GaAs single crystals is also a viable method of growth of InP single crystals. The target carrier concentration is 1016 5 atoms per cubic centimeter and the dislocation density is 1,000 gae/cm2. The vertical gradient freeze method demonstrates a robust growth process for semiconductors, even in extreme conditions. For the first time, a single crystal of GaAs has been grown in a microgravity environment.

Using a vertical gradient freeze process for growing GaAs single crystals is a powerful way to grow GaAs nanocrystals without any additional chemical additives. The process requires high heat and is highly complex, but has great potential. However, it has been used by numerous researchers worldwide. The process also uses a semi-insulating gallium arsenide material for control.

The vertical gradient freeze method involves moving the crucible and heater relative to each other. This provides a temperature gradient, which in turn enhances single crystal growth. The resulting crystal has excellent electrical properties due to a large degree of uniformity in the electrical characteristics across the cut wafer's surface. This method is an excellent way to develop advanced devices. It is an exciting new method for making GaAs semiconductors.

What are Some Vertical Gradient Freeze Grown Gallium Arsenide Benefits

The benefits of vertical gradient freeze grown gallium aristotes are countless. The materials can be used in a variety of electronic, optoelectronic and optomechanical applications. These materials can be grown on silicon substrates using various techniques including a Czochralski growth method. The resulting crystals are suitable for a variety of industrial applications, such as solar cells and memory chips.

The vertical gradient freeze method has been used to grow large, state-of-the-art single crystals. The resulting seeded 50 mm diameter crystals are stable against thermal type conversion and display excellent radial uniformity. In addition, these wafers exhibit very low dislocation densities. These properties make them suitable for a wide range of applications, including solar cells, photovoltaics, and nitric acid detectors.

The vertical gradient freeze method has been used to grow large, state-of-the-art single crystals. The resulting seeded 50 mm diameter crystals are stable against thermal type conversion and display excellent radial uniformity. In addition, these wafers exhibit very low dislocation densities. These properties make them suitable for a wide range of applications, including solar cells, photovoltaics, and nitric acid detectors.

In addition to the advantages of vertical gradient freeze, this technology also exhibits the linear electro-optic effect. The linear electro-optic tensor r represents the change in the refractive index of the material under an electric field. This change in the crystal's refractive index is observed for both parallel-polarized and slanted light. Here, r is the linear electro-optic tensor, while n0 is the refractive index in the absence of an electric field. This effect allows for better control over the properties of the crystal and is an excellent tool for many different applications.

The vertical gradient freeze method produces large, high-quality single crystals. The seeded 50 mm crystals have lower dislocation density than alternative methods, and show excellent radial uniformity. Undoped semi-insulating GaAs is also thermally stable and resists type-conversion. For example, semiconductor devices requiring very high temperature and high sensitivity.

What are Some GaAs Semiconductor Applications?

In addition to semiconductor applications, gallium arsenide can exhibit the linear electro-optic effect. This phenomenon occurs when an external electric field passes through the crystal. In contrast, the linear electro-optic effect is a highly efficient way to generate energy through solar panels. Moreover, it has several other advantages as well. For example, it can be used in high-voltage electronics.

There are three main processes for the production of GaAs wafers. The most common is the vertical gradient freeze. The second is the Bridgman-Stockbarger method. In both, the dislocation density is lower with the vertical gradient freeze process. The third method involves a horizontal zone furnace where the gallium-arsenic vapors react.

This method uses an electric field to grow GaAs wafers. The result is a high-purity, low-cost single crystal with a reduced dislocation density. Another method uses liquid encapsulated Czochralski growth. This technique also produces higher-purity single crystals that are semi-insulating. The latter is more expensive than the former, but it is easier to scale and more effective.

The most common vertical gradient freeze technique is the most common way of growing GaAs wafers. The Bridgman-Stockbarger method is an alternative, but it is less efficient. The two processes are similar, but the vertical gradient freeze method is more complex and more reliable. In addition, the EEX method is a more expensive process and has lower quality.

There are several advantages to the vertical gradient freeze process. The material is non-toxic and produces high-purity single crystals. Its crystalline structure is symmetrical and oriented 100°. The material is used in a wide variety of industries, including aerospace, medical devices, and electrical equipment. The chemical process of producing the wafers is efficient and produces large volumes of GaAs.

The vertical gradient freeze method is a high-quality, large-scale semiconductor. The process can be used to produce large single crystals. The seeded 50mm-diameter crystals have very low dislocation densities and high radial uniformity. In addition, the undoped semi-insulating GaAs is stable against thermal type conversion. It can be used in applications ranging from solar cells to medical equipment.

Compared to other semiconductor materials, gallium aristotes have a higher electron mobility and lower resistance. They can function at high frequencies of 250 GHz. Their large energy band gap makes them suitable for use in HEMT transistors. They can also be used in quantum well devices. As they are not susceptible to oxidation, they are excellent for microwave point-to-point links and radar systems.

VGF Grown Gallium Arsenide Research

The market for solar cells (GaAs) is segmented by type and application and analyzed by country, application type, product type and region. This part of the report highlights the key trends and trends in the solar cell GaAs market and focuses on key strategies that have been taken to consolidate the market share of VGF-grown gallium arsenide in various applications. The countries and applications provide information on market size and volume as described above. This offering from ResearchAndMarkets.com has been included in the list of market reports under the title "Global Solar Cells." [Sources: 2, 8, 13]

At the same time, gallium arsenide (GaAs) wafers are classified by type, application and geography. Based on this type, the Gallum Ar seneside wafer segment is divided into VGF - growing gallium arsenide, Ga as a whole (GAAs) , Gaas, which are grown in the form of silicon and GaAS, which are grown on silicon oxide (GOS). [Sources: 7, 10]

We analyzed the gallium arsenide (GaAs) wafers and analyzed their chemical composition and properties. These include the composition of the gallium arsenide wafer material, the type of silicon oxide and the geology of the region. [Sources: 2, 11]

The report also provides a detailed analysis of the gallium arsenide wafer market (GaAs) on the world market. Our study takes into account the impact that the gallium arsenalide wafer market (GaAs) will have on the market during the forecast period. The report analyses the growth rate, market share and market size of each segment and sub-segment in terms of revenue. [Sources: 15, 17]

The report predicts that global gallium arsenide wafers (GaAs) will grow at an annual rate of 6.5% and reach $1 billion by 2020. Over the forecast period, growth, which is expected to be driven by the growth of the gallium arsenide wafer market and its sub-segments, would be xx%. [Sources: 6, 10]

Based on the product range, the gallium arsenide market is divided into VGF Grown GaAs and LEC G Grown Ga and their sub-segments. According to the report, V GF Ggrown GaA has a 32.07% share of the global gallium arsenide wafer market in the first half of the forecast period (2015-2020), while Lec GainedGaAs has gained the share (32%) and the second half (30.06%). [Sources: 12, 20]

GaAs crystals can be doped with various elements to achieve the required electrical conductivity on semi-insulated wafers. The semiconductor compound of group III (V), which consists of two elements, gallium arsenide and zinc oxide (ZO), is of particular importance. These two elements combine in a zinc-iris crystal structure to form a III-V semiconductor and form the basis for the high-performance, cost-effective and high-performance silicon wafer. [Sources: 3, 4, 16]

In an exemplary implementation, the crystal growth process may include controlled temperature gradients associated with crystals based on group III, while maintaining the temperature gradients of the crystal melt for a certain period of time. GaAs crystals by annealing at high temperatures of up to 1150 cr and quenching at a temperature of 10 - 15 degrees C for at least 10 minutes. During the quenching process, gliding and contortions occur and an effective dissolution is achieved. [Sources: 1, 14]

The material is synthesized and then processed into crystals in quartz boats using b2o3. GaAs crystals have a semi-insulated EPD of about 600 cm2, which is achieved for Ga crystals with a diameter of 3A3. The materials are then synthesized and the crystals do not have to be boron-free, but the boron concentrations are quite low due to the use of b. [Sources: 5, 14, 21]

GaAs crystals with a diameter of 3A3 and a partially insulated EPD of about 600 cm2 can be grown on partially insulated substrates at a temperature of 1,000 degrees Celsius. [Sources: 19]

If the process proceeds as planned, the molten gallium arsenide will solidify in its entirety into seed crystals, the orientation of which is determined by the crystal orientation. Crystals are grown in a horizontal zone furnace that reacts with gallium arsenic vapor and in which crystals grow, creating a thin layer of molten material with a surface area of about 1 cm2 and a temperature of 1,000 degrees Celsius. GaAs crystals are cooled in a 4-pipe (2 inches) that carries about 2.5 gallons of liquid and 1 gallon of water per hour. [Sources: 0, 3, 16, 18]

It is well known in the gallium arsenide industry that there is a high demand for gallium arsenide substrates for a wide range of applications. In line with innovation in this area, the substrate has been shaped to a surface of around 1 cm2 and a temperature of 1,000 degrees Celsius, and has proven itself in high temperatures, high pressure and high humidity. It is well known that the use of gallium as a substrate for the production of high-quality, high-performance and low-cost gallium arsenic-rich materials is one of the most important applications of gallium arsenic as an energy source. [Sources: 9, 14]

The high component yields lead to highly integrated GaAs circuits and high-performance, low-cost gallium arsenide semiconductors. The use of the VGF - grown substrate for the production of semi-insulated GaAs wafers - has led to the development of a wide range of high-performance and cost-effective semiconductor devices with high efficiency. [Sources: 9, 19]

Sources:

[0]: https://patents.google.com/patent/CN106319630A/en

[1]: https://ui.adsabs.harvard.edu/abs/1993PhDT.......281C/abstract

[2]: https://markets.businessinsider.com/news/stocks/gallium-arsenide-wafers-2018-global-market-to-reach-1-3-billion-by-2023-drivers-trends-challenges-and-opportunities-1027356029

[5]: https://www.universitywafer.com/gallium-arsenide-gaas.html

[6]: https://www.empiricaldatainsights.com/industry-report/gallium-arsenide-gaas-wafer-market/367/

[7]: https://www.prnewswire.com/news-releases/gallium-arsenide-gaas-and-compound-semiconductors-technologies-services-market-to-reach-more-than-us-430-mn-by-2025-qy-research-879565472.html

[8]: https://www.openpr.com/news/2130467/gallium-arsenide-germanium-solar-cell-gaas-market-2020

[9]: http://www.freepatentsonline.com/7566641.html

[10]: https://www.reportsinsights.com/industry-forecast/Gallium-Arsenide-GaAs-Wafers-Market-122351

[11]: https://www.absolutereports.com/global-gallium-arsenide-gaas-wafer-market-13909363

[12]: http://algosonline.com/news/gallium-arsenide-market-growth-trends-and-forecast-2020-2025-

[13]: https://www.databridgemarketresearch.com/reports/global-gallium-arsenide-germanium-solar-cell-gaas-market

[14]: http://www.google.com/patents/US20110089538

[15]: https://bulletinline.com/2020/09/07/latest-developments-cagr-of-gallium-arsenide-market-2020-sales-volume-production-demand-on-global-regional-country-level/

[16]: https://patents.justia.com/patent/4923561

[17]: https://www.syndicatemarketresearch.com/market-analysis/gallium-arsenide-gaas-wafer-market.html

[18]: https://en.wikipedia.org/wiki/Gallium_arsenide

[20]: https://www.marketwatch.com/press-release/gallium-arsenide-market-size---top-manufacturers-entry-global-industry-analysis-market-share-growth-trends-segmentation-and-forecast-2025-2020-07-14

[21]: http://www.jos.ac.cn/app/article/app/doi/10.1088/1674-4926/37/6/063002?pageType=en