Can you please provide a formal estimate for 25 of Item #783. Our Researchers have use for MEMs and microfluidic fabrication and particle synthesis.

What is Micro Electromechanical Systems (MEMS)

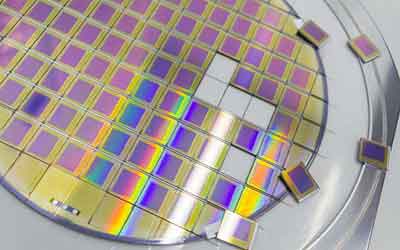

Silicon to Fabricate MEMS and Microfluidics

A photonics engineer requested the following quote:

Reference #275166 for specs and pricing.

BF33 Substrates Used to Fabricate Optical MEMS Devices

A researcher at an optical institute requested a quote for the following borofloat 33 window.

We need 200mm diameter 750um thick borosilicate wafer for a batch of 50, 100 and 1000 for an optical mems that will be fabricate on the substrate. Edges: C radius ground & polished.

Reference #223687 for specs and pricing.

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

Lithium Niobate (LiNbO3) Wafers for MEMS Research

I am interested in: A layer of SAW Grade 128Y-Cut LiNbO3 bonded to a SCS wafer The X axis of the 128Y-Cut LiNbO3 should be parallel to the [100] direction of the SCS (45 degrees rotated with respect to the primary flat of the SCS). If you can produce this, what would be the diameter of the bonded wafer? Is 4’’ (10[cm]) diameter possible? What is the range of layer thicknesses you are able to produce for each of the LiNbO3 and the SCS layers? Is it possible to produce ~20[um] layer of LiNbO3 on top of a ~280[um] wafer of SCS? What is the lowest resistivity of the SCS you are can offer? If the SCS is not uniformly doped, is it possible to bond the LiNbO3 to the higher doped surface of the SCS wafer? Are you able to produce a metallic coating (e.g., a layer of NiCrAu) on top of the LiNbO3 layer for electrodes? If not, what other material can you offer as electrodes? In either case, what is the expected (minimal) thickness of the electrode layer? Can you cut the wafer into strips of 10[mm] width, along the [100] direction of the SCS, after fabrication?

What SOI Wafers Can Be Used for MEMS?

A researcher contacted for a silicon-on-insulator quote for their MEMS project.

Researcher:

We are interested in the mechanical properties for a MEMS application so the resistivity and other electrical properties dont matter for us.

Ideally 100mm diameter but that is flexible since we will dice and fab on a carrier wafer.

As for handle thickness, ~300 to 700 micron. Ideally around 500 micron

Bow and warp are important to keep small as well.

We are interested in SOI wafers with ~3-7 micron device layer and ~1-2 micron BOX layer. Do you have any such wafers in stock in small quantity, ~3-5 wafers in total.

Please reference #265173 for pricing.

EPI Ready Silicon Wafers Used to Fabricate MEMS Devices

A corporate scientist requested a quote for the following Epi Ready Silicon Substrates.

Question:

I am interested in some your Epi-Ready Silicon wafers, need to confirm the price for one wafer.Also, can you tell me a little about ITME and for what purpose these junctions were done? Any information about quality of layers, i.e., lifetime etc.

UniversityWafer, Answered:

ITME is an institute for electronic materials research located in Europe.

The listed Epi wafers are tail-ends of various production runs made for various research purposes.

YES, you wore me down, I will sell you even a single wafer from any or all of the listed cassettes at the indicated prices, but I have to add a a fee for opening the various cassettes, extracting required wafers in a clean-room and repackaging what is left. I am sorry, this is work that somebody has to do and be paid for. It is easier to just pick a cassette off the shelf and send it to you.

An Epi wafer with p-n or n-p junction can be used in various ways.

- You can apply metallization on both sides, dice the wafer it into thousands of chips and each one of them is a diode.

- You can use it as a starting point to make individual transistors or integrated circuits.

- You can use the Epi wafers in fabricating MEMS devices, using the p-n or n-p junction as the etch stop in anodic etching - you can make pressure sensor membranes by etching away the substrate wafer and leaving the Epi layer as a membrane.

How is Lithography used to Fabricate MEMS Sensors and Actuators

Lithography, in the context of MicroElectroMechanical Systems (MEMS) fabrication, is a lot like using a very detailed stencil to draw complex patterns on a tiny canvas. However, instead of using paint and paper, we're using light (or other types of radiation) and a material called a substrate, often made from silicon.

Here's a simplified explanation of the process:

-

Preparation: First, the substrate (like a silicon wafer) is covered with a light-sensitive material, called a photoresist. You can think of this as preparing your canvas for drawing.

-

Exposure: Then, a mask (like a stencil) with the desired pattern is placed over the wafer. Light is then shone onto the mask. The light goes through the clear parts of the mask and exposes the photoresist underneath.

-

Development: After exposure, the wafer is immersed in a special solution that removes the exposed or unexposed areas of the photoresist (depending on whether the photoresist is positive or negative), revealing the pattern that was on the mask.

-

Etching: Once the pattern is transferred onto the wafer, the uncovered areas can be etched away using chemicals or plasma (a state of super-hot, charged gas), leaving behind a 3D structure that matches the pattern from the mask.

-

Repeat: The process can be repeated multiple times with different masks to create more complex structures, like the tiny mechanical structures found in MEMS sensors and actuators.

So, in summary, lithography in MEMS fabrication is like a meticulous process of drawing, etching, and repeating to create tiny mechanical structures from a flat piece of material. It's one of the core technologies that has enabled the miniaturization revolution in electronics and continues to play a crucial role in the production of MEMS devices.

What are Optical MEMS Devices?

These are used in industrial automation for applications like laser scanning, precision alignment, and machine vision. For instance, in quality control, optical MEMS can be used for fast, accurate inspection of products on a production line.

Borofloat 33 Wafers are often used to fabricate optical mems devices.

What are Microactuators?

MEMS-based microactuators are used for precision movement control in machines. These are typically used in microrobotics and precision assembly lines where small and accurate movements are required.

Researchers have used (112) orientation silicon wafers for their projects.

MEMS Component Applications

Most MEMS devices like sensors are used for measuring and detecting real world conditions (sensors) and, or generating motion (actuators).

What Wafers are Used in MEMS Research?

A MEMS research lab conducting research on devices made from layers of lithium niobite (LiNbO3) bonded to substrates of [100] single-crystalline silicon (SCS).

See below for more specs or Reference #265307 for a quote.

Thin Silicon Used to Fabricate Micro-Mirrors

Micro-mirrors: micro-mirrors are tiny, movable mirrors etched onto a silicon substrate. They can be individually controlled to tilt in specific directions. One popular application is in Digital Light Processing (DLP) projectors, where an array of these micro-mirrors is used to reflect light and create an image.

A undergrate molecular engineering student requested the following quote:

We are a group of students. We're told UniversityWafer, Inc. supplies specialty silicon wafers. May we ask if you have thin silicon wafers that are flexible and thus can be bent?

We are actually currently researching into a protein called reflectin from squids which can reflect different colours (depending on the thickness) when coated onto a substrate. We are working together with the Molecular Engineering Lab and have so far found silicon wafers to be the best substrate, obtaining coatings such as this one:

We believe that the coating requires the substrate to be as reflective as a mirror, as silicon is. However, a truly interesting property of reflecting which has been reported previously and what we wish to research into, is its ability to change colour dynamically after being coated. To do so, previous research has claimed stretching of the coating to act as a mechanical stimulus to change its thickness and thus colour. We hypothesize that we may be able to achieve the same results using a thin silicon wafer that is flexible which would also stretch the coating when it bends. Therefore, thin silicon wafers are required, however we can only find overseas suppliers that sell in bulk. Do supply such flexible thin silicon wafers?

Reference #206773 for specs and pricing.

MEMS Optical Switches

Optical switches are used in telecommunication networks to manage and route optical signals. They provide high-speed, low-loss switching for better data transmission.

Variable Optical Attenuators

Variable Optical Attenuators: precisely control the intensity of light in fiber-optic communication systems, helping to avoid signal distortion.

A electrical engineer requested a quote for the following:

Attenuator 8keV-25keV Double-side polished SINGLE CRYSTALS Filter # Min. Qty. Si (um) (in.) TiO2 (um) (in.) InSb (um)* (in.) CdTe (um)* (in.) 1 3 48 0.0019 2 3 97 0.0038 3 3 193 0.0076 4 3 387 0.0152 5 3 773 0.0304 6 3 1547 0.0609 7 3 479 0.0189 8 3 958 0.0377 9 3 1915 0.0754 10 3 459 0.0181 428 0.0169 11 3 918 0.0361 865 0.0341 12 3 1835 0.0722 1712 0.0674 Note: * InSb is preferred; if not available, CdTe may be the substitute Chemical Description Element Name Si Silicon TiO2 Titanium dioxide (titanium) InSb Indium antimonide CdTe Cadmium telluride

UniversityWafer, Inc. Quoted:

InSb Item #6707

2" (111B) 500um SSP

Reference #266967 for specs and pricing.

MEMS Spectrometers

Spectrometers: Miniaturized spectrometers using optical MEMS technology can be used for various applications, from environmental monitoring to health diagnostics.

MEMS Optical Scanners

Optical Scanners: are often based on a micro-mirror platform, can deflect a light beam in one or two dimensions. They are used in applications such as barcode readers, LIDAR systems for autonomous vehicles, and biomedical imaging.

Fabricating MEMS optical scanners, like all MEMS devices, involves several precise specifications for the substrate. While the specifications can vary depending on the design and intended application of the optical scanner, there are some common features. Here are some of the general substrate specifications:

-

Material: The most commonly used material for fabricating MEMS devices, including optical scanners, is silicon due to its excellent mechanical properties and compatibility with standard microfabrication techniques. In some cases, other materials like glass, quartz, or certain polymers may be used.

-

Orientation: The crystal orientation of the silicon wafer is important. Usually, (100) silicon wafers are preferred for MEMS fabrication because of their predictable etching characteristics.

-

Diameter: The wafer diameter can vary, but 100mm (4 inches) to 200mm (8 inches) wafers are typical for MEMS fabrication.

-

Thickness: The thickness of the wafer is crucial because it can impact the device's mechanical properties. For MEMS optical scanners, the thickness often ranges from a few hundred micrometers to about a millimeter.

-

Surface: Depending on the fabrication process, the wafer may need to be single-side polished (SSP) or double-side polished (DSP). The surface roughness also matters, as a smoother surface can result in better device performance.

-

Doping: The type (n-type or p-type) and level of doping in the silicon wafer can impact the electrical properties of the device, which may be important in certain MEMS optical scanners.

-

Layer Specifications: For some MEMS optical scanners, additional layers may be added to the silicon substrate, such as a silicon dioxide (SiO2) layer for insulation, or a layer of polysilicon or metal for creating the movable elements of the scanner.

Note: This is a general overview and the actual specifications can vary widely based on the specific design and fabrication process of the MEMS optical scanner. Always refer to the design specifications provided by the MEMS designer or a MEMS fabrication professional for the most accurate information.

What Silicon Wafers are Used to Fabricate MEMS Devices?

Micro-Electro-Mechanical Systems (MEMS) is the integration of mechanical elements, sensors, actuators, and electronics on a common silicon substrate through microfabrication technology. While the electronics are fabricated using integrated circuit (IC) process sequences (e.g., CMOS, Bipolar, or BiCMOS processes), the micromechanical components are fabricated using compatible "micromachining" processes that selectively etch away parts of the silicon wafer or add new structural layers to form the mechanical and electromechanical devices.

MEMS promises to revolutionize nearly every product category by bringing together silicon-based microelectronics with micromachining technology, making possible the realization of complete systems-on-a-chip. MEMS is an enabling technology allowing the development of smart products, augmenting the computational ability of microelectronics with the perception and control capabilities of microsensors and microactuators and expanding the space of possible designs and applications.

UniversityWafer, Inc. and our partners have been supplying Silicon Wafers for MEMS applications for a number of years. Depending upon the MEMS application, these wafers have been either Epitaxial Wafers or Silicon Substrates, Float Zone or CZ types.

For example, 100mm to 150mm, N- Epitaxial Wafers on P- Substrates, Double- Sided Polished (DSP) structures are used for automotive pressure sensors. These are supplied with different epitaxial layer resistivities and thicknesses.

Here is an example:

Automotive Pressure Sensor Epitaxial Wafers - Double Sided Polished

- Substrate - 100mm, P type, Boron, <100> Orientation

- Wafer Alignment: <100> +-1 degree

- Surface: Both sides polished per SEMI Std. M1-1296

- Wafer thickness: 366+-15μm

- Wafer diameter: 100 mm +- 0.2 mm

- Wafer Type: Boron <100>, On Orientation

- Resistivity: 6.0- 8.5 ohm-cm.

- Total Thickness Variation (TTV) <5.0μm

- (Other diameters up to 200 mm are possible).

- N Type Epitaxial Layer

- Epitaxial Layer Resistivity: 4.5+-13% ohm-cm

- Epitaxial Layer Thickness: 13.0+-5%um

(Virtually all other combinations of resistivity and thickness are possible)

Silicon Wafers to Fabricate MEMS-Type Structures from Gold

A physics research professor requested a quote for the following:

We are trying to develop a new process using thin silicon, but we

don"t know if it"s going to work or not.

However, we could test our process with some scrap thin-silicon

material, if you have some amount of breakage in your thinning

process.

We would be looking for silicon <=50um thick, with a preference for <=25um and a minimum thickness of maybe 10um. DSP would be safest but

we can probably use SSP just as well.

We would dice your scrap pieces down to about 1cm x 1cm for our tests,

so we"d like to get pieces bigger than 1 cm x 1cm if possible. It's

OK if the pieces are different thicknesses, and any doping level is

fine.

We could start testing with just a few cm^2 of material.

We want to try using thin silicon as the lower level of a mask for electroforming MEMS-type structures from gold. silicon may provide substantial advantages for our process because it will be resistant to the solvents and solutions used in subsequent processing steps and can be completely removed from complex shapes using XeF2.

Reference #202020 for specs and pricing.

What Is Micro Electromechanical Systems (MEMS)?

What is micro electromechanical systems (MEMS)? MEMS are ![]() regular mechanical systems at a small scale. They are often fabricated using silicon electronic chip technology, including nanometer-scale etching and photolithography. These systems are not downscaled mechanical systems, but rather scale differently as linear dimensions are increased. For example, an ant's mass and strength are proportional to its volume and cross-sectional area.

regular mechanical systems at a small scale. They are often fabricated using silicon electronic chip technology, including nanometer-scale etching and photolithography. These systems are not downscaled mechanical systems, but rather scale differently as linear dimensions are increased. For example, an ant's mass and strength are proportional to its volume and cross-sectional area.

MEMS devices are often equipped with different types of transduction mechanisms, and their use is increasingly increasing. Typically, they use mechanical-to-electrical transducers to control their behavior and interface with other domains. However, other types of transducers are available for different applications. For example, a MEMS device can be controlled by an external circuit, allowing the device to respond to environmental changes. Some systems can even use micromirrors to project images in high-definition video.

While micro-electromechanical systems can be considered micro, they also combine other elements, such as sensors, into their designs. A micro-sensor is a device that measures a mechanical signal and converts it to an electrical signal. The device can then respond to that signal. Micro-electronic systems are becoming an increasingly important part of many industries, such as the medical field. And in the foreseeable future, they'll continue to expand into more diverse applications.

Currently, there is an acute need for advanced simulation tools to help designers realize their designs. Traditional analytical tools have poor accuracy in predicting the behavior of a device. It is typically trial-and-error, with several iterations to satisfy performance requirements. Prototypes are costly and time-consuming, so the availability of a suitable design tool can make a significant difference in commercial product development. When properly used, these tools can help to develop new MEMS components and systems.

How Do MEMS Benefit The Aerospace Industry?

The aerospace industry needs to be convinced that the MEMS technology can deliver game-changing characteristics. A MEMS device can replace an existing legacy system, but it faces a steep learning curve, and a low-cost device with an unknown performance profile could negatively affect the learning curve. Therefore, MEMS should be considered early in the product development process. Ultimately, MEMS devices it will save time, money, and energy, and it can dramatically improve reliability and performance.

What Silicon Wafers are Used to Fabricate MEMS Devices?

A Silicon Wafer is a silicon wafer that is used to fabricate micro electromechanical systems (MEMS). These devices are typically built using a batch process that mimics the steps used to fabricate an IC. During the MEMS manufacturing process, polycrystalline silicon is deposited and patterned with a number of sacrificial layers such as silicon dioxide. Then, the patterned layers are etched or dissolved to reveal a three-dimensional structure. These devices are manufactured using the same batch processing techniques that are used in IC manufacturing. This allows them to be built on one silicon wafer and requires no subsequent assembly.

The fabrication process involves etching and deposition of alternating structure and sacrificial materials on a silicon wafer. The sacrificial materials are patterned photolithographically and epitaxially on a silicon substrate. Once the structures have been etched, the wafer goes through a release etching process to selectively remove the sacrificial materials. The resulting structure is a complex movable structure that can serve as a sensor or actuator.

The complexity of MEMS technology is a major hurdle, but the advantages outweigh the disadvantages. MEMS components must be expensive, reliable and robust, and their packaging must be highly reliable. These devices are often referred to as nanoelectromechanical systems and are used to develop low-cost, low-power, and high-performance systems on a chip. So, what is the future of these devices?

UniversityWafer, Inc. has silicon wafers as thin as 2 micron. You can buy ultra-thin silicon wafers wafers online.

What is the Future of MEMS?

Miniaturization is driving the development of MEMS, or micro electromechanical systems. They are now widely used in consumer electronics, wearable devices, medical instruments, and other applications. MEMS have numerous advantages over traditional electronic components including:

- low power consumption

- small size

- high accuracy

Unlike traditional electronic components, MEMS devices are inexpensive, highly reliable, and can be soldered directly onto a circuit board. These advantages make the technology an attractive choice for small and high-volume applications.

MEMS can act on real-time information about our physical environment. By developing these sensors, we can improve our lives, our understanding of the world, and our productivity. This research is supported by the director of our college, the professor at ADCET, and R. A. Jadhav, and the technical assistance at ADCET. The researchers thank their mentors and instructors for their support of their work. Listed below are some examples of applications of MEMS.

What Companies Have a Strong MEMS Program:

- Panasonic Corporation

- Robert Bosch GmbH

- STMicroelectronics N.V.

- Texas Instruments

Large companies typically specialize in low-cost components and packaged solutions for applications in end markets such as biomedical and automotive. Smaller firms often develop custom-made solutions and absorb the costs associated with custom fabrication. Both large and small companies typically invest heavily in R&D to explore new MEMS technologies.

What are Some MEMS Devices?

MEMS are semiconductor devices with mechanical elements that combine signal processing with sensing or actuation. These devices can be integrated, with mechanical parts and components, or may contain both. Fully integrated MEMS are designed using computer-aided design and are produced in batches using VLSI-based fabrication tools. These devices are fabricated by a high-throughput manufacturing process that reduces the cost and time of prototyping.

There are many applications for micro electro mechanical systems. Some of these devices are intended for planned employment, such as micromirrors that transmit information. Other components are used opportunistically, such as pressure sensors and accelerometers. Nevertheless, they are already important devices in many industries and are expected to continue to grow in number and diversity. To read more about MEMS, read on! Let's explore some of the ways these devices can help us improve our lives.

One of the best examples of how MEMS technology can be used is in automobiles. Many modern automobiles use MEMS sensors. Automotive airbag systems use sensors that employ MEMS technology. It pioneered the use of surface micromachining and realized co-integration between MEMS and integrated circuits. There are many examples of how these devices can improve our lives. For example, they are being used in smart dust sensors and high-definition projection systems.

Why Are Silicon Wafers Used to Fabricate MEMS?

You might be wondering why silicon is used to fabricate MEMS. To understand this  question, you should first learn about how the process of fabrication is performed. In this article, we will discuss some of the most important aspects of MEMS fabrication. Silicon wafers are used because they can be easily fabricated into MEMS. Silicon wafers are made of silicon, which is the most common semiconductor.

question, you should first learn about how the process of fabrication is performed. In this article, we will discuss some of the most important aspects of MEMS fabrication. Silicon wafers are used because they can be easily fabricated into MEMS. Silicon wafers are made of silicon, which is the most common semiconductor.

Silicon is used in most integrated circuits in consumer electronics. It is a low-cost, high-quality material that can incorporate all the electronic functionality needed. This material has significant advantages over other materials because it is almost a perfect Hookean material with no hysteresis or fatigue, and it can withstand billions to trillions of cycles. The process of building MEMS components using silicon involves using thin films.

Another important characteristic of silicon wafers is that their critical dimensions are much larger on the back side than on the front. Because of this, a backside silicon wafer has a larger opening than its front side. When the substrate is processed, the etching process will release the mechanical structure. This process is known as anisotropic etching and it is widely used in fabricating MEMS devices.

The fabrication of MEMS devices utilizes the same techniques that were first developed for semiconductors. During this process, a thin film material is deposition onto a silicon substrate, which acts as a temporary mechanical layer. This layer is removed to release the structural layer, which can then move. This process has many benefits, and the process has helped us develop devices that are incredibly small.

MEMS Technology

UniversityWafer, Inc and our partners have the substrates and expertise to help you design, process and package MEMS devices. We have substrates for Deep Reactive Ion Etching (DRIE), non-standard silicon wafers including hard to find orientations to develop unique MEMS devices, thin films and more.

- Micro-electro-mechanical systems (MEMS)

- Sensors

- Accelerometer - Found in phones, airbags bridging mechanical motion and electrical signals

- Actuators

- Microfluidics

- Microfabrication

- Nanotechnology

- Mirrors - Used for HDTVs and Projectors