We need Silicon-on-Sapphire (SoS) wafers to see if we can photoexcite and modulate terahertz radiation with thin flims silicon.

Terahertz Circuits Using Quartz Windows

Substrates Used to Fabricate Terahertz Beamsplitters

A Quantum Nano-Optoelectronics researcher requested a quote for the following:

We want Float Zone Silicon (HRFZ Si) , diameters of 50.8 mm (2inch), and thickness of 3mm as Terahertz beamsplitters. Do you have these in stock? Please let me know the price and lead time.

UniversityWafer, Quoted:

3inch FZ Silicon Wafer for Terahertz beamsplitter

Float Zone Silicon (HRFZ Si) >10000 Ohm.cm, diameters of 76.2 mm (3inch), and thickness of 3mm Double side polished as Terahertz beamsplitters.Qty. 25pcs

Reference # 269299 for specs and pricing

Get Your Quote FAST! Or, Buy Online and Start Researching Today!

SoS Substrates to Photoexcite and Modulate Terahertz Radiation

A deep THz modulation researcher requested a quote for the following:

Reference #ONL29063 for specs and pricing.

Gallium Phosphide Substrates for Terahertz Detection

A postdoc requeste a quote for the following:

I would like to ask about the unit prices for the following Undoped GaP wafers (for terahertz detection), double-side polished, that are advertised in your webpage https://www.universitywafer.com/III-V/Gallium_Phosphide/gallium_phosphide.html The items of interest are: GaP Wafer, undoped (110) 10x10x0.5 mm, DSP GaP Wafer, undoped (110) 5x5x0.2 mm, DSP.

Referece #255350 for specs and pricing.

Time Domain Spectroscopy in TeraHertz Spectral Range

A nanotechnology researcher requested a quote for the following:

I am looking for rectangular high resistivity Silicon windows; The characteristics are the following : Length : 201mm Width : 65mm Thickness : 1.6mm; 3.1mm, 3.8mm Both side polished. Resistivity : >10 ohm-cm Parallelism: the best possible Wavelength range: 200 GHz to 5 THz Application: Time domain spectroscopy in TeraHertz spectral range Comments : these windows are to do THz-TDS experiments. Parralelism is important and Windows will be mounted in specific flange at Brewster angle to close a cell under vacuum for spectroscopic of gas and particule in a controlled air flow. If you have better product for this spectral range and this experimental conditions, your advices or comments are welcomed. Quantity : 5 of each

UniversityWafer, Inc. Quoted:

Pls see below for the offer on required rectangular high resistivity >10K Ohm.cm Silicon window

- Rectangular high resistivity Silicon windows; Length : 201mm Width : 65mm Thickness : 1.6mm,Both side polished. Resistivity : >10K ohm.cm Parallelism: the best possible,edge beveled,Quantity : 5

- Rectangular high resistivity Silicon windows; Length : 201mm Width : 65mm Thickness : 3.1mm,Both side polished. Resistivity : >10K ohm.cm Parallelism: the best possible,edge beveled,Quantity : 5

- Rectangular high resistivity Silicon windows; Length : 201mm Width : 65mm Thickness : 3.8mm Both side polished. Resistivity : >10K ohm.cm Parallelism: the best possible,edge beveled,Quantity : 5

Reference #258947 for specs and pricing.

ZnTe Substrates for Terahertz Electro-Optical Sampling

A PhD candidate requested a quote for the following:

I am looking for ZnTe (110) crystal with 0.5mm thickness and GaP (110) with around 0.4mm thickness for terahertz electro-optical sampling purposes. Could you provide me with a quote for similar products you have? We are looking for one of each crystal with 5mm or 10mm diameters and anti-reflective coatings on one side for 800nm if possible.

UniversityWafer, Inc. Quoted:

We can supply only uncoated crystals.

GaP (110), 5х5х0.5 mm, dual sides polished 60/40 (Scr/Dig), minimum order quantity: 2pcs at $950.00 for 1pc.

ZnTe (110), dual sides polished 60/40 (Scr/Dig):

diam. 5 x 0.5 mm, 2pcs

diam. 10 x 0.5 mm, 2pcs

Shipment: 6-7 weeks ARO.

Reference #270778 for more specs and pricing.

Gallium Phosphide Substrates for Terahertz Detection

A physics graduate student requested help with the following:

Reference #274896 for specs and pricing.

Undoped Silicon Used to Fabricate Terahertz Circuits

A Phd candidate requested a quote for the following:

My motivation in writing the projects was mainly purchasing high resistivity 8" silicon wafers. No need to have official quotations right now, however I would be pleased to hear from you about your altertnatives for 8" high resistivity Si wafers. Is there any option with resistivity of 1 kohm-cm or any higher resistivity?

We are focused on the development of terahertz and photonics passive circuits.

UniversityWafer, Quoted:

Item# 3328: 100mm Undoped<100>>20,000 ohm-cm 525um SSP Prime

Reference #263806 for specs and pricing.

What Substrates are Used to Fabricate Terahertz Circuits?

Quartz is a widely distributed mineral known for its use in crystal-controlled electronic devices. It is also used for energy healing, divining and enchanting.

When irradiated with femtosecond laser pulses, the substrate gets temporarily conductive. This enables the generation of short-lifetime carriers that induce pulsed electromagnetic waves. This is how the terahertz spectrum can be generated.

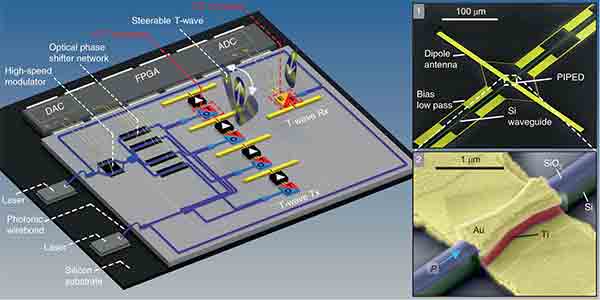

Terahertz Circuit

Silicon

The ability to interact with terahertz waves offers many opportunities for advancements in wireless communication, real time and high-resolution imaging, material characterization and space communications. However, the cost and size of terahertz devices still prevent them from entering widespread use. One of the key barriers is the lack of an efficient terahertz signal receiver. Currently, receivers are built using expensive horn antennas or bulky waveguides and amplifiers. Despite this, terahertz circuits can be fabricated on silicon and other semiconductor and dielectric substrates.

Silicon is a naturally occurring element with a long history of use. It is usually found linked up with oxygen molecules as silicon dioxide (SiO2). This compound is used in a variety of low-tech creations, including bricks and ceramics. It is also the raw material for modern electronics like computers, smartphones and radios. It was first isolated in 1824 by Jons Jacob Berzelius, who also discovered thorium and cerium. The refined version of silicon is the backbone of many electronic components, such as transistors that amplify or switch electrical currents.

In order to realize THz modulation, a dielectric substrate needs to have a high optical refractive index. This can be achieved by coating the substrate with a high-quality monolayer graphene film. When irradiated with laser light, these films can generate carriers that change the conductivity of the substrate and modify the transmission of THz waves.

In order to increase the efficiency of THz devices, it is important to reduce the losses of the system. There are several factors that contribute to these losses, including ohmic losses, mismatch between the modal fields of a straight waveguide and grating, and scattering on imperfections in the grating structure. Graphene-based THz detectors have shown promise for overcoming these losses. They can achieve much higher cutoff frequencies than conventional p-n junction and Schottky diodes, but still maintain high DC performance.

Gallium Arsenide

Gallium arsenide (GaAs) is a compound semiconductor. It consists of the elements gallium and arsenic, which are both members of the III-V group in the periodic table. Its unique properties make it an important material in cutting-edge technologies. For example, GaAs is used in telecommunications and solar cells. Telecommunications applications rely on the technology’s ability to transmit data at high speeds over long distances, while solar cells use the element’s resistance to radiation damage.

Computer chips, solar cells and other electronic devices all begin their journey from raw crystals to final products by being fashioned into what the industry calls wafers. Wafers are flat, circular platters of purified materials that subsequent manufacturing steps create computer chips, solar cells and other electronic devices on top of. Silicon is a common choice for these types of substrates, but Stanford researchers have developed a new process that makes an alternative material called gallium arsenide cheaper to produce.

In their report, published in MRS Communications, the Stanford scientists describe how they made GaAs wafers by combining the Bridgeman technique for creating single-crystal gallium arsenide with the encapsulated Czochralski method for growing multilayer structures. Their wafers were then used to fabricate a two-wire THz directional coupler and an arrayed distributed microwave module (ADM).

Because gallium arsenide is toxic, workers in the microelectronics industry are cautioned to follow all safety policies when handling the material. Air and wipe samples should be regularly collected from areas where worker exposure is likely to occur, including crystal growth, crystal puller cleaning, crystal sawing and wafer polishing and dicing. The samples should be analyzed for inorganic arsenic. This analysis will help identify any potential toxicity issues and allow for appropriate controls to be put in place. Inhalation and ingestion of gallium arsenide particles can lead to lung and bone cancer.

Indium Phosphide

Indium phosphide is an excellent choice for terahertz (THz) devices because it has a better electron velocity than silicon. This makes it ideal for devices that require high speeds such as fast transistors and resonance tunneling diodes.

It is also a good choice for devices that require low thermal expansion. Indium phosphide is a binary semiconductor that has a face-centered cubic crystal structure similar to GaAs and most other II-V semiconductors. It is produced by direct combination of highly purified white phosphorus and indium iodide at elevated temperature and pressure. It has a very high melting point and boiling point, making it easy to work with.

The crystal growth of indium phosphide is relatively simple and straightforward, even compared to other III-V semiconductors. The etch pit density (EPD) is one of the best indicators of quality, along with the molar ratio of the indium-organic compound to the phosphorus source. The ratio must be above 50:1 in order to prevent phosphorus escape during deposition. A ratio lower than this will result in a generally poor morphology for the deposited indium phosphide.

VITAL supplies InP wafers in sizes ranging from 2" to 4" for telecommunications and microelectronics applications. The InP wafers can be provided un-doped, Fe-doped, or S-doped.

InP substrates are used to grow a variety of III-V heterostructure devices such as lasers, LEDs, and photodetectors. These substrates are extremely expensive and must be kept clean in order to produce reliable devices. They are usually Chemically Mechanically Polished and Plaranrized (CMP) to ensure a smooth surface that is ready for device fabrication. They can also be Laser Assisted Lithography (LAL) processed to remove impurities such as SiO2 and oxide contamination. In addition, the wafers are usually annealed to reduce their stress. This helps to improve their electrical properties and make them more durable.

Silicon-on-Insulator

Silicon-on-Insulator (SOI): SOI is a silicon-based material that offers better performance at high frequencies compared to regular silicon. It consists of a thin layer of silicon atop an insulator, often silicon dioxide. This can help to reduce parasitic capacitance and improve device performance at terahertz frequencies.

Quartz: Quartz is sometimes used as a substrate material for terahertz antennas due to its low loss characteristics at terahertz frequencies.

Fused Quartz Windows for Terahertz Measurements

Fused quartz (also known as fused silica) substrate are used to fabricate terahertz circuits. Fused quartz very low coefficient of thermal expansion, excellent thermal shock resistance, high chemical purity, and excellent optical properties.

In the context of terahertz circuits, the most critical properties of fused quartz are its low loss (or high transparency) in the terahertz frequency range and its high dielectric strength. These properties make it an ideal substrate for certain types of terahertz devices, such as antennas and waveguides.

Moreover, quartz substrates are often used in the fabrication of devices that require high-temperature processing steps, as the material can withstand these temperatures without degrading. Fused quartz is also chemically inert, which makes it suitable for many fabrication processes.

An engineer at a startup requested a quote for the following:

We are a startup and we are looking for quartz and polystyrene windows for Terahertz measurements (0.1 to 3 THz). The thickness we are looking for is 0.5 mm / 1 mm / 2 mm and the diameter is 50 mm. We would be grateful if you could kindly let us know if you have the same and the pricing and availability.

For the fused quartz (JGS1) as mentioned by you, can you please let me know the % Transmittance and % Reflectance in the 100 - 3000 micron range (Terahertz range)? We need high transmittance of the Terahertz radiation through the windows.

Reference #264112 for specs and pricing.

Thin Quartz Wafers for Specialized Terahertz Wave Applications

A THz Structural Dynamics researcher requested the following quote:

Hello University Wafer Team, I am interested in how thin of quartz wafers you are able to produce/sell. I am interested in thicknesses below 50 microns, if that is achievable, for specialized Terahertz applications. Looking forward to your response!

he lateral dimensions are not important to me, but 1-inch diameter would be convenient, as well as 1cmx1cm. I would require double side polished, although surface roughness is not so strict. The <5 angstrom suggested on your webpage is already much better than I would require for my THz-wave applications.

What is more critical is the thickness. I would like to have a single crystal with a thickness of 10 microns, with a tolerance of p/m 1 or 2 microns. If that thickness is just too thin, 20 or 30µm could also work, with a similar tolerance.

Are such pieces possible to produce? Thank you for your time and thoughtfulness, and I'm looking forward to your response!

UniversityWafer, Inc. Quoted:

Crystal Quartz Wafer

1", 0.0457mm thick, DSP

Quantity: 10 pieces

Reference #272647 for more specs and pricing.

Terahertz Circuits Quartz

Terahertz electronics (TE) is a new technology that extends the field of electronics to the THz frequency range. Teraherz's electronic technology has paved the way for the development of highly integrated radar and communication systems and a wide range of other applications.

What Are Terahertz Circuits?

The novel optical control method, which uses photogenerated free carriers in semiconductors, was introduced for the first time and a reconfigurable microwave circuit protocol type based on a photo-induced line structure was demonstrated to verify the feasibility of using this method to realize tunable and reconfigured microwave circuits, in which it is presented and discussed in detail. The ability to integrate passive THz waveguide circuits on large surfaces of substrates was investigated. Teraherz technology to enable multipliers to work with higher frequencies and to make technical proposals to overcome the difficulties of developing hybrid integrated circuits for radio frequency applications. [Sources: 1, 7, 12]

The active circuit concept is based on a combination of terahertz technology and a novel optical control method, in which photogenerated free carriers are used in semiconductors and photovoltaics in the form of photodetectors. [Sources: 0]

The transmitter and receiver share a common RF port with a bandpass filter that is tuned to simultaneously transmit and receive in different bands, and are integrated with transceivers that operate on lower frequencies. An on-chip antenna is used to drive the waves in the same direction as the transceiver, but at a lower frequency than the transmitter. [Sources: 13]

A ring of electronic oscillators does the same, and a circuit coupled to the oscillator can set the frequency at which it jams. This means that even if we only look at transistors, the active circuit can reach lower THz frequencies and in the future may have the ability to extend its range of action further into the full THZ band. If transistor speeds are to be really useful, they must be used not only at circuit level, but also at chip level. [Sources: 0, 8, 10]

The main reason for this is that there are only a few transistor blocks on the market today based on transistors. Due to the lack of availability of integrated THz circuits, there is no easy way to build a powerful, low-power, and low-cost transistor - only circuits we are building. [Sources: 8, 12]

THz emitters are built with Schottky diode multipliers and mixers, which are used to convert the signal to THz frequencies up and down. [Sources: 8]

Due to limited semiconductor processes, terahertz frequency multipliers based on monolithic integrated circuits are not suitable for the production of high-performance, low-power, and low-power teraflops. Recently, however, the demand for high-performance TeraHertz waveguides with high power has increased significantly. These waveguide connections form the basic components of an integrated circuit and can also be integrated via this topology. They form a low-loss, planar THz waveguide, but lack high control over the frequency range of the signal, such as that of a high-frequency multiplier. Therefore, they can be approached in a different way and form the basis for a new generation of low-cost, fast, ultra-energy, multi-frequency wave rides. [Sources: 1, 3, 5, 12]

Recent scaling advances, which have again increased the use of terahertz waveguides for high-performance, low-power teraflops, have equipped hemts for TeraHertz operations and paved the way for teraslight ICs. Ter aHERTzarmed as Ingaas channels are the basis for building a new generation of low, fast, ultra and multi-frequency energy waves with high power and low power in integrated circuits. [Sources: 0]

Dielectric waveguides - based devices are used to develop novel integrated terahertz circuits for applications in antenna arrays and sensors. [Sources: 9]

This structure is particularly interesting because nano-antennas can be integrated into terahertz circuits within a few millimeters. In this embodiment, the disclosed design of the non-contact probe comprises a THz / mmW beam tilted antenna integrating a single waveguide, waveguide-to-wave circuit and microantenna. The design is difficult to design a frequency multiplier as there is no direct contact between the beam and the antenna, but there are a number of designs that include conductors and slow wave circuits to interact with terasheet waves in a linear electron beam. [Sources: 1, 2, 3, 6]

Commercial providers have begun to develop and manufacture frequency extension modules for use in terahertz applications such as radio frequency communications, radio frequency communications and radio frequency management. [Sources: 0]

Research has focused on terahertz monolithic circuits and integrated circuits, solving many of the problems associated with the design and development of high-performance, low-power and high-frequency circuits. Advanced technologies such as frameless membranes have been developed, but VDI is the most advanced and cost-effective approach to terAheart circuit design. This research focuses on the development and construction of ter aherts in monolithically integrated circuits, with a focus on high performance and low cost. [Sources: 1]

In earlier experiments, the researchers produced chips that had previously generated volumes of electricity on silicon chips at terahertz frequencies. Based on such approaches, it has been shown that terAheart circuits with high performance, low cost and high performance can be processed at a cost of less than $1,000 per ter. [Sources: 10, 11]

Sources:

[1]: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7143111/

[2]: https://www.sciencedaily.com/releases/2018/06/180626112956.htm

[3]: http://www.freepatentsonline.com/9488572.html

[4]: https://electronicsforu.com/technology-trends/tuning-terahertz-electronics

[5]: https://ece.engin.umich.edu/event/terahertz-communications-at-300-ghz-devices-packages-and-system

[6]: https://en.wikipedia.org/wiki/Terahertz_metamaterial

[7]: https://curate.nd.edu/show/z890rr20k89

[8]: https://www.mdpi.com/1424-8220/19/11/2454/htm

[9]: https://www.nsf.gov/awardsearch/showAward?AWD_ID=1032610

[10]: https://news.cornell.edu/stories/2012/07/new-way-generate-terahertz-radiation

[12]: https://grantome.com/grant/NSF/ECCS-1032610

[13]: https://www.intechopen.com/books/electromagnetic-materials-and-devices/terahertz-sources-detectors-and-transceivers-in-silicon-technologies